What is Polycarbonate Trays? Durable, Hygienic, and Long-Lasting Solution for Catering and Food Companies

The equipment used in the mass catering sector must promise much more than ordinary household products. Trays used hundreds or even thousands of times a day must simultaneously meet criteria such as durability, hygiene, cost advantage, and longevity. This is where the concept of polycarbonate trays comes into play.

In this article, we will discuss the question, “What is a Polycarbonate Tray?” focusing on the technical, operational, and commercial aspects for catering companies and food production/distribution companies.

What is Polycarbonate? (Brief Technical Definition)

Polycarbonate (PC – Polycarbonate) is a raw material with high impact resistance, can be produced transparent or opaque, and is classified as an engineering plastic. It's a strong alternative for professional kitchens with high-performance expectations in intensive use and frequent washing cycles.

- Very high impact resistance (resistance to breakage)

- Stable structure against heat and chemicals

- Long-lasting usage

- Production suitable for contact with food

- Maintains its form despite frequent washing

What is a Tray?

A tray is a system that particularly ensures the orderly and rapid presentation of meals on a single tray or partitioned serving equipment, especially in mass catering service. It is a critical component in catering operations for service speed, order, and hygiene.

Areas where tray use is prevalent:

- Catering companies

- Factory canteens

- Hospital and school kitchens

- Military facilities

- Hotels and resorts

What is a Polycarbonate Tray?

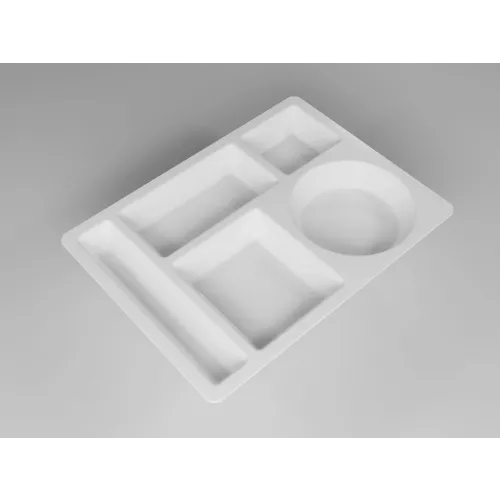

Polycarbonate trays are serving equipment entirely made from polycarbonate raw material; they have a partitioned structure and are extremely durable, hygienic, and long-lasting. They minimize the risk of breakage in high-paced kitchens and support operational continuity.

Polycarbonate trays are developed for high-use areas, reducing the risk of breakage and providing a suitable tray solution for professional kitchens.

Why Should Catering Companies Prefer Polycarbonate Trays?

1) Significantly Reduces Breakage Problem

One of the biggest problems in catering operations during transportation, serving line, dishwashing, and storage processes is breakage. Ceramics and some alternative materials can be more sensitive in cases like falling, impact, and stacking.

Polycarbonate trays have high impact resistance; thus, they help reduce product losses and minimize the risks of occupational accidents.

2) May Be More Economical in the Long Run

Although the initial purchase cost may seem higher compared to some alternatives, polycarbonate trays, offering long-lasting use, may provide an advantage in terms of total cost of ownership (TCO). The decreased need for constant renewal makes budget planning easier.

3) Supports Hygiene Standards

In the mass catering industry, hygiene is not a choice but a necessity. Polycarbonate trays, with their non-porous surface, can make cleaning and hygiene management easier.

- Non-porous surface

- Tendency not to retain odors

- Resistance to stains and discoloration

- Compatibility with industrial washing processes

4) Compatibility with Industrial Dishwashers

Industrial dishwashers operate with high temperatures, strong detergents, and intensive washing cycles. High-quality polycarbonate trays help in maintaining form during these cycles and ensure operational continuity.

Polycarbonate Trays vs Melamine Trays (Brief Comparison)

| Feature | Polycarbonate Tray | Melamine Tray |

|---|---|---|

| Impact Resistance | Very high | Medium |

| Breakage Risk | Low | Medium / High (depends on usage) |

| Longevity | High | Medium |

| Hygiene | High | Medium |

| Dishwasher Resistance | High (depending on product quality) | Wear may occur over time |

| Total Cost | May be advantageous in the long run | May increase with frequent renewal |

Advantages in Catering Operations

Operational Speed

Durable equipment causes less “attention/damage” concern in the service and transportation processes. This supports the team working faster and more stable.

Occupational Safety

Durable serving equipment makes a significant contribution to preventing cuts and injuries caused by broken plates.

Inventory Management

The decrease in frequent breakage and renewal needs makes stock planning easier and reduces supply pressure.

Corporate Image

Uniform, quality, and clean-looking serving equipment creates a more professional perception from the customer's perspective.

Types of Polycarbonate Trays

According to menu planning, service order, and portion variety, different division numbers and designs can be preferred:

- 4-compartment tray

- 5-compartment tray

- 6-compartment tray

- Tray with soup container

- Tray with non-slip base

Food Contact Safety

In trays selected for professional use, suitability for food contact is a critical criterion. The manufacturer's declarations, test reports, and compliance documents (if any) should be examined.

Note: Not every product in the market may meet the same quality standards. It is important for catering companies to prefer reliable manufacturers and suppliers with regular quality control processes.

Who Should Use Polycarbonate Trays?

- Catering companies

- Factory canteens

- Hospitals

- Schools and universities

- Hotels and resorts

- Military units

- Corporate food production facilities

What to Consider When Buying?

When buying polycarbonate trays, not just price, but also long-term performance and supply continuity should be evaluated:

- Quality of the raw material

- Food contact suitability and documentation

- Division depths and ergonomics

- Compatibility with industrial washing

- Long-term supply assurance

- Availability of spare/complementary products

Conclusion: A Smart Investment for Catering Companies

In summary, polycarbonate trays offer a strong solution for businesses looking for durability, hygiene, and operational efficiency. They help raise the quality standard in mass meal service through reduced breakage-induced losses, maintaining form in washing cycles, and professional appearance.

If you wish, I can also rearrange this content: in the format of a product page, B2B catalog text, or landing page.